When you think about supply chain automation what often comes to mind are mega-corporations with expensive and complex robotics running people-less factories and warehouses with endless arrays of software and robots moving materials and churning out products. How can a small manufacturer possibly afford automation? The answer is they can, but with more practical and reasonably priced “mechanical” automation technologies that can be applied in the areas of materials handling and movement. One example of an effective mechanical automation smaller manufacturers can adopt is called “gravity flow racking”.

What is gravity flow racking and how does it work?

Gravity flow racking systems use storage racks with metal rollers placed at downward angles to allow materials (parts or components) and products to “flow” using gravity. If you have ever taken a trip to the supermarket to buy your favorite beverage whether by the case or can you likely utilized a flow racking system. Most gravity flow racking will also let you adjust rack slot width to accommodate multiple size parts or products. Flow racking can be configured in a variety of lengths, shapes, and flow angles. Steeper roller angles are often needed for lighter materials. For heavier materials, shallower roller angles, metal stops, dividers, and spring latch systems can be combined to safely control flow.

How are gravity flow racks used?

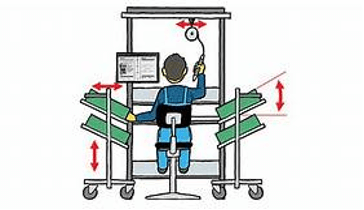

Gravity flow racks can be used to feed materials and components directly into an assembly station thus reducing the time and effort required by the assembly employee to acquire and move parts or components. Gravity flow racks can also be used as an effective and simple way to move work in process from one assembly station to the next without requiring the operator to physically lift and move product to the next operation station, reducing operator motion and improving safety. Gravity flow racking systems also accommodate good visual replenishment. By walking down the backside of the flow rack, it is easy to see which slots are empty or low requiring replenishment to keep assembly work moving. A good way to determine probable areas for using gravity flow racking is to take a walk through your production/assembly operations looking for areas where employees are repetitively moving, retrieving, lifting, twisting, and transferring materials. These areas can be probable points where gravity flow racking applications could be useful to reduce motion keeping production work flowing while improving safety.

Where to find Gravity Flow Racking

Gravity flow racking systems are abundant and come in a variety of configurations. Reasonably priced, used gravity flow racking in good condition can be picked up through a variety of secondary resellers. A quick internet search under used flow racking in your geographic area will provide a lengthy list of resellers.

Gravity flow racking is just one of the many automation solutions for material handling challenges. If you would like to discuss this or other options please feel free to call or email me.

![]() Tim Allen is the VP of Management Consulting at Pragmatek and specializes in helping small and mid-size manufacturers improve business profitability. Contact: (214)-493-9111, tim.allen@pragmatek.com, LinkedIn

Tim Allen is the VP of Management Consulting at Pragmatek and specializes in helping small and mid-size manufacturers improve business profitability. Contact: (214)-493-9111, tim.allen@pragmatek.com, LinkedIn