Many manufacturers are starting to turn to automation to address increasing competition and a lack of skilled production workers. COVID and retiring Baby Boomers have exacerbated the labor shortage and made a more urgent issue.

Most manufacturers do not have an automation strategy. This gap in planning results in failed projects, lost improvement opportunities, and disappointment with automation from business owners. Having a well thought out strategy that is implemented vigorously ensures increased competitiveness and growth opportunities.

What Are the Elements of An Automation Strategy?

A complete automation strategy should include the following elements:

- Vision and description of why and how the business will automate

- Identification and prioritization of automation opportunities

- High level assessment of project risks and impacts (financial, quality, delivery, safety)

- Identification of additional skill sets needed to plan, implement, and support the automation technology (often overlooked)

- Financial projection of capital spending, resource investments, and estimated return on investment for each automation project

What Is Required to Create an Automation Strategy?

All business executives develop and update business strategies with input from key leaders of all disciplines. An Automation Strategy is similar to an Information Technology Strategy in that it requires special technical knowledge to evaluate processes, alternative solutions, estimate impacts, and assess implementation risks.

- Secure Experienced Technical Resources

The first and most important step in the process is to secure the proper technical resources to lead the completion of the automation strategy. For this effort a competent third party should be actively involved to ensure completeness. This person should be able to educate the executive team in the process, automation alternatives, risks, and required organizational support.

- Identify and Prioritize Improvement Opportunities

Analyze the product groups, process flows, and performance related data to identify and prioritize improvement opportunities. Identifying likely project risks, assessing process variability, and contacting potential automation suppliers for feasible solutions should be part of this effort.

Analyze the product groups, process flows, and performance related data to identify and prioritize improvement opportunities. Identifying likely project risks, assessing process variability, and contacting potential automation suppliers for feasible solutions should be part of this effort.

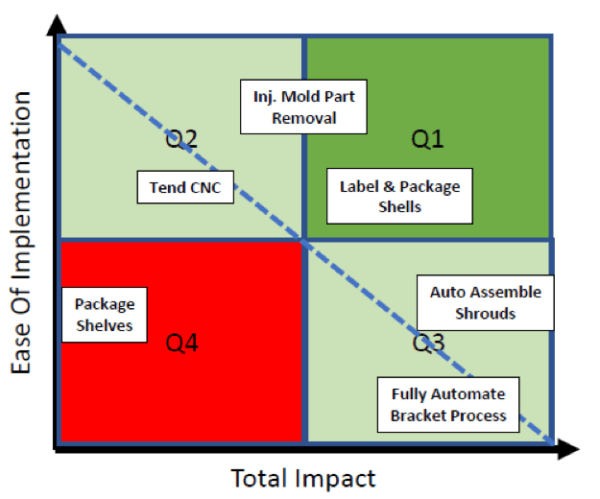

A four-quadrant prioritization map can be used to compare and contrast opportunities in a facilitated team meeting. Project risks should be included in any rating of Ease of Implementation.

- Determine Support Skills and Resources for Success

Introducing automation for the first time can be quite painful if key process insights and support elements are not in place. Part and process variability must be characterized and controlled, equipment, molds, dies, and fixtures must be maintained to a high level, and the automation itself requires routine maintenance and programming.

Specific skills are needed for each of these areas and may not be in the current organization. Ignoring these or under-investing in support can cause project failure with a large loss of investment.

- Build a Pro-Forma Financial Model

This should include each improvement opportunity, the estimated investments, additional support resources, and projected impact on KPIs. This forms the baseline for measuring actual performance once the strategy is implemented. Leading firms build this projection into the budget once the funding has been approved and project timing finalized.

- Finalize and Integrate with Other Initiatives

Once this hard work is done it is critical to summarize the strategy and communicate how it supports and is integrated with other key business imperatives such as Continuous Improvement, New Products, or business expansion.

In Summary

Before diving into an expensive and risk automation initiative, step back and examine your strategy and its key elements. Most risks can be avoided and project success assured by following this proven process.

About the Author – Paul Neblock is Partner at APEX Management Partners, LLC with 30+ years of experience implementing automation strategies Paul@apexmanagementpartners.net 847-558-9008