The Execution Element

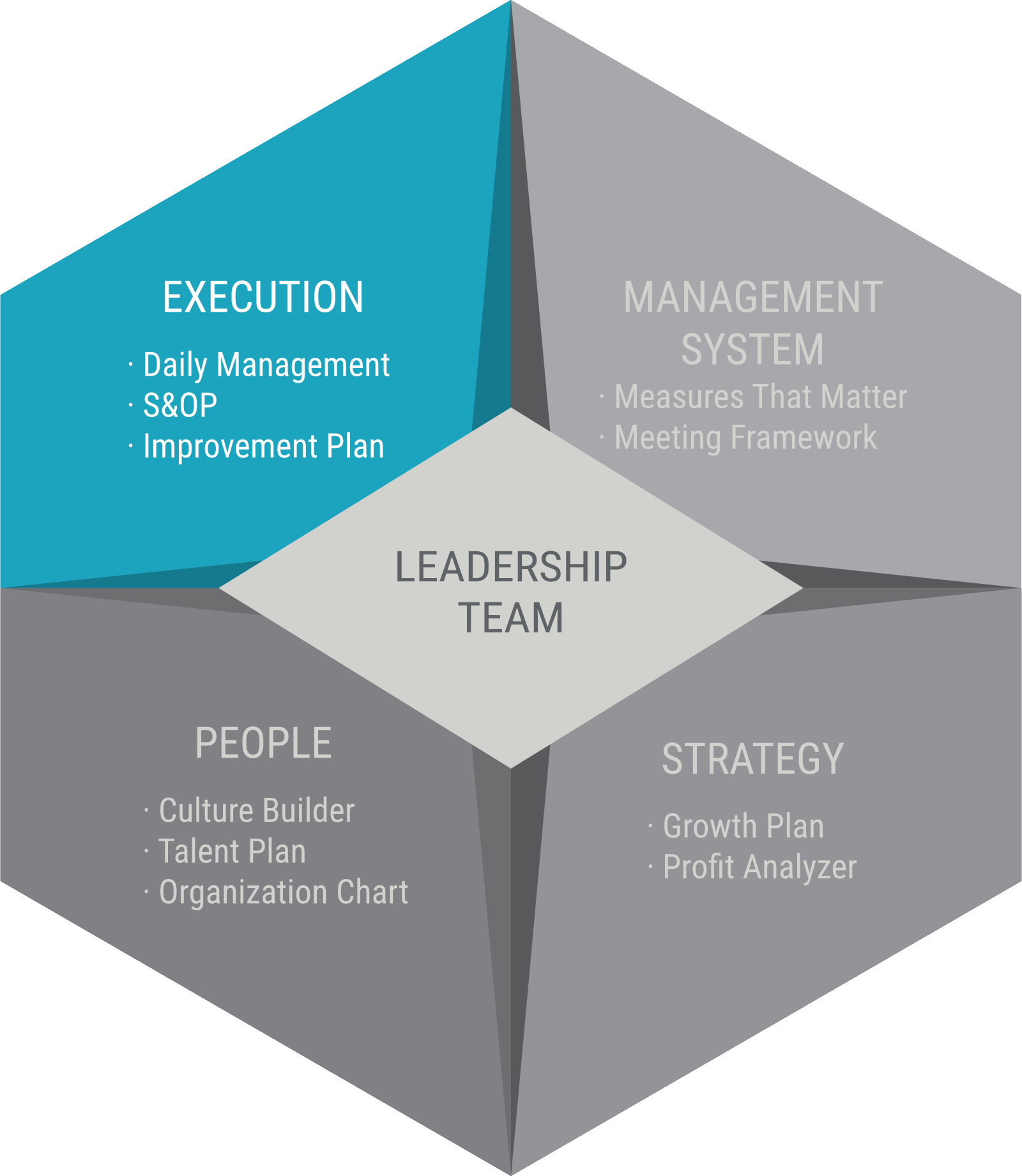

The Manufacturing Leadership System™

The Execution element has the tools needed for the company to have consistent execution that is continually improving.

The Daily Management System addresses real-time issues so that daily performance goals are achieved.

The Sales & Operations Plan (S&OP) ensures that operations and the sales team are aligned about the capacity requirements of the business for the next 13 weeks.

Lastly, the Improvement Plan is the roadmap that focuses continuous improvement efforts on the most important goals.

Daily Management

The Daily Management System is a set of tools and practices that enables day-to-day execution. Lean people often refer to it as tier meetings. Essentially, it is a set of brief meetings, often multiple times throughout the day, at the work center level. Results are tracked and issues are flushed. Issues that cannot be handled from within the work center are raised up to the next level.

Experienced Lean organizations attributed up to 50% of their gains to their daily management system.

A Daily Mgmt. System is Needed if:

- Daily performance is erratic.

- Teams are missing their targets.

- Continuous improvement results are not reaching their potential.

- Additional capacity is needed.

Process

- 2-day working session to:

- Learn Daily Mgmt Principles

- Design Communication Boards

- Write standard work for tier meetings and the escalation process

- Create the rollout plan

- Pilot in one work center

- Rollout to other work centers & improve

Fees

$7,000+

The fee covers the facilitation of the 2-day session. Sometimes on-site, one-on-one coaching can accelerate results. The scope and nature of this coaching will be determine based on your specific needs.

S&OP

Companies need to plan their capacity for the future with a goal of keeping capacity (and costs) aligned with the volume of sales that will be coming in. With today’s labor market, it’s important to be looking well into the future to anticipate capacity requirements so that hiring and training can start well in advance of when the capacity is needed.

The 1-page Sales & Operations Plan is the tool that facilitates this decision. It is a one page spreadsheet that contains the sales forecast, production requirements and requisite staffing levels.

With this tool in hand, the senior leadership team can jointly make decisions about what the next 13-26 weeks will bring so that capacity plans can be put in place.

Check out my blog article to learn more.

The 1-Page S&OP is Needed if:

- Production capacity is out of sync with sales.

- Sales blames operations for not shipping on tiime.

- Operations blames sales for a bad forecast.

Process

- 4-hours of pre-work by me to build the framework of the model

- 4-hour working session to refine the model

- Establish the meeting cadence

- Practice and refine

Fees

$5,000

This fee includes the building of the initial 1-page plan framework, conducting the working session, and participation in 2-3 of the S&OP meetings

Improvement Plan

Manufacturers must continually improve in order to survive, and many have adopted methods like Lean as the framework for their improvement efforts. Unfortunately, most continuous improvement programs fail to deliver meaningful or game-changing results.

The purpose of The Improvement Plan is to ensure that all of the hard work that goes into your continuous improvement program pays off. We’ll work together to understand where you are today and the goals that you want to achieve, and we’ll create a roadmap to get there.

Typically the roadmap extends for 1-2 years, at which point we’ll want to take stock of the progress that has been made and the challenges that were encountered to create the plan for the next 1-2 years.

The Improvement Plan is Needed if:

- Improvement efforts have yielded local improvements, yet those efforts haven’t impacted the overall business substantially.

- The company lacks a formal continuous improvement program.

- Improvement efforts tend to backslide over time.

Process

- 2 4-hour working sessions

- Session 1: Understanding the current state & goals

- Session 2: Developing the roadmap

- Quarterly 2-hour check-ins

Fees

$5,000

The fee covers the initial sessions to create the roadmap, the first three quarterly reviews, and ad-hoc consultations within reason.